Nature is a treasure trove of incredible engineering feats, showcasing remarkable adaptations and design principles. For example, think about the strength and structure of spider silk webs, honeycomb, or bird feathers.

Nature is a treasure trove of incredible engineering feats, showcasing remarkable adaptations and design principles. For example, think about the strength and structure of spider silk webs, honeycomb, or bird feathers.

Therefore, innovators and engineers often look to nature for inspiration when creating new materials and structures. Natural systems have evolved and adapted to optimize their functional performance and efficiently use the available resources. This can lead to some spectacular phenomenon.

Inspired by these natural biological systems, Professor Yaning Li and her team at the Mechanics, Biomimetics, and 3D Printing Research Lab are designing new materials with unique mechanical properties and fabricating them using 3D printing technology.

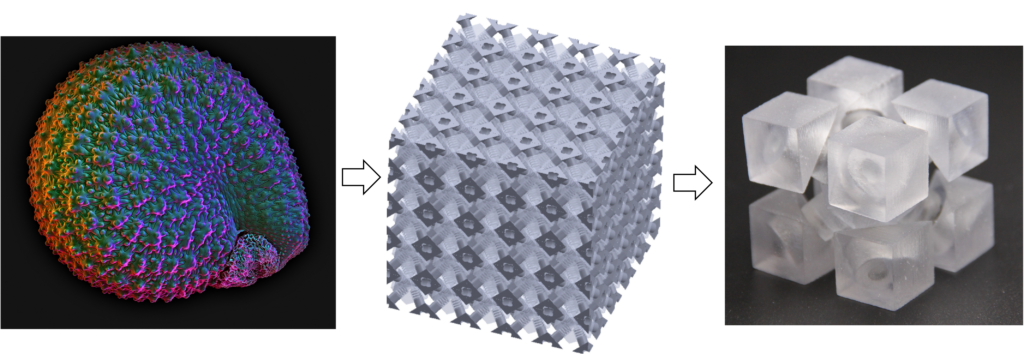

Specifically, Li and her team are designing a better way to protect electric vehicle (EV) batteries against hazards like accidents and fires. The project enhances the safety and durability of EV batteries by protecting them while allowing them to transmit their load and dissipate energy efficiently. They are developing what’s called a tiled auxetic metamaterial (TAM) that draws its original inspiration from the intricate microstructure of common millet seedcoats and woodpecker beaks.

This work has earned Li and her team selection as one of the Fall 2022 Spark Fund awardees.

Creating Novel 3D-Printed Materials Inspired by Nature

The investigation began ten years ago when the team examined the microstructure of various plant seedcoats, including common millet and portulaca. They discovered a unique jigsaw puzzle-like pattern known as sutural tessellation, characterized by wavy sutures between cells. Fascinated by its mechanical properties, the researchers secured government funding to delve deeper into the science behind these structures.

By exploiting the seedcoat microstructure’s efficient load transmission and energy dissipation capabilities, the researchers sought to develop a mechanical metamaterial capable of safeguarding EV batteries. Leveraging the potential of multi-material 3D printing, they have created innovative designs that share the same fundamental mechanical mechanism — although they no longer resemble the original seed coats they studied.

“Materials in nature have many interesting mechanical and multi-functional properties,” says Liu. “I am a scientist and an engineer, so I am naturally curious to discover the relationship between natural materials and engineering. 3D printing provides a bridge between these two worlds.”

Looking towards the future, the team envisions integrating TAMs into new models of EVs within the next 5 to 10 years. This ambitious goal aligns with their belief that the knowledge generated from their research will have far-reaching implications. The team anticipates that TAMs, along with other designs employing similar principles, will find application in the protection of vital assemblies and equipment across various length scales, extending beyond the realm of EVs.

Commercialization with the Spark Fund

Working with the CRI and the Spark Fund has allowed the researchers to advance their technology into the commercialization stage.

“For commercialization, market and timing are very important,” says Li. “Identifying the correct market at the right time is key for the successful launch of new products. The ability to consult with colleagues at the CRI and beyond proved to be very helpful in finding the right market and timing to target.”

Like many other applicants, the team was able to receive feedback from the program’s review panel and R&D team that allowed them to refine their proposal, network with industry contacts, and ultimately obtain the support they needed to propel their research forward.

“The team at the CRI provided tremendous support throughout this part of the commercialization journey,” says Li. “They helped to file patent applications, answered our questions, and walked us through every step of the way.”

The Spark funds will play a crucial role in furthering the research and enabling the team to delve deeper into applications for mechanical metamaterials, bio-inspired engineering, and 3D printing.

Learn more about Professor Li’s research and the other Spark Fund Award grantees here.